Airstorm appeared at the 4th Mexico Assembly Wiretech exhibition

Exhibition overview

MEXICO ASSEMBLY WIRETECH has be held in the Chihuahua World Expo Convention and Exhibition Center on October 2-3,2024. Better known as Wiretech Expo,is an event focused on uniting the cable processing companies. The goal is to provide attendees full access to equipment, tools, materials, and supplies used in manufacturing wire harnesses, as well as in its inspection and repair.At the same time, it brings together top enterprises, industry experts and technology innovators from all over the world to discuss the latest progress and future trends of the industry.

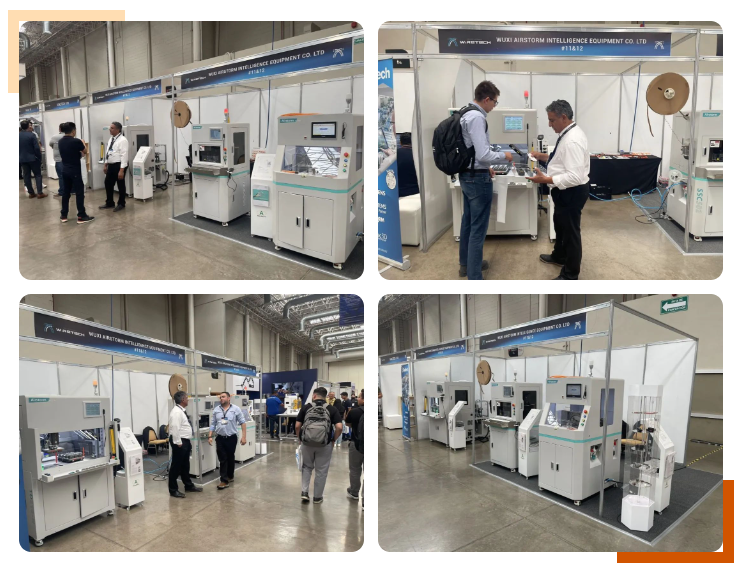

Exhibition Site

Wuxi Airstorm Intelligence Equipment Co., LTD. (booth no.: 11 & 12), as a well-known enterprise of wiring harness processing equipment, with a number of star products appeared in this exhibition, fully demonstrated the company's profound accumulation and strong strength in the field of intelligent manufacturing. Through on-site demonstration and interactive communication, Airstorm has established close contact with partners and potential customers from all over the world, and takes this exhibition as an opportunity to join hands with more partners around the world to inject inexhaustible power into the development and manufacturing of wire harness processing equipment, and lay a solid foundation for further development of overseas markets!

● SSC502 is designed for processing the jacket cable and twisted cable. lt integrates three functions,sealing-stripping-crimping.

Default configuration:

Active paperroller丨Carrier cutter丨 Bad crimping cutter丨Wire colordetection丨OES CFM丨Seal S14 self-learning丨Cutting off check丨Servo motor with automatic adjustment of crimping height ,suitable for 30/40 applicator丨Crimping height can be set丨Three-core-cable can be customized

Technical Spec:

Wire Size:0.13-4mm²(Single-core model:Max.6mm²)

Jacket Stripping Length:>26mm(with seal)

Stripping Length:1-8mm

Press Force:3T

Machine Processing Time:3S

Total Cycle Time:4.1S

● HSC800 is applied to the processing of the high-voltage coaxial cable of new energy. lt can perform up to seven functions: outer jacket stripping, foil removing,shield cutting,shield flipping,shield brushing,secondary shield cutting and inner insulation stripping(also canhalf-stripping).

Technical Spec:

Cable Cross section:2.5-120mm²(2.5-4mm² needs sample to confirm)

Jacket Stripping Length:5-120mm

Foil Removal Length:5-100mm

Shield Braid Cutting Length:10-95mm

Inner Insulation Stripping Length:5-95mm

Machine Processing Time:20S(-5) ; 30S(-7)

Total Cycle Time:25S(-5) ; 35S(-7)

● TD210-NP blind seal machine is a half automatic machine which is applied to blind seals/sticks in automotive connectors. The machine is configured with a maximum of 3 sets of insertion nozzle, supporting the production of 3 different seals/round pins in the same connector.Making the changeover more flexible. Efficiency of 0.5S/seal can be achieved by using the double insertion model.With the emergence of new processes, we have added a reverse function ontop of the TD210-NP equipment: punching function. According to different process requirements .TD210-NP can be achieved for both plugging and punching,with seamless connection and no tool replacement.

Technical Spec:

Biggest Connector:L80*W50mm

Plug Type:no direction on Yaxis

Blinding Seal Time:<1S/hole

Punching Time:0.5-0.8S/hole

● TD-X2030C ultrasonic automatic wire harness welding machine can be used to weld various shapes of wire harnesses, bunches and copperwires. These wire harness products are mainly used in automotive, wireharness and process control equipment and other products, and are generally mainly used in automotive wire harness production. This device can complete the welding process in one go. Compared with the terminal crimping welding and resistance welding process, ultrasonic welding has the advantages of clean and efficient, no flux required strong conductivity, resistance close to 0 and so on.

Horn Set

Technical Spec:

Capacity:0.35-25mm²

Max.Power:3KW

Max.Amplitude Output:54μm

Air Filtration Accuracy:5μm

Working Temperature:-5℃~40℃

Working Humidity:30%~95%

Exhibition site

Look forward to the future

This exhibition is of great significance to Airstorm. On the one hand, it shows the strength and innovation ability of Airstorm in the field of intelligent manufacturing, enhancing the brand image and visibility; on the other hand, it also provides valuable opportunities and platform for Airstorm to expand overseas market. In the future, Airstorm will continue to deeply cultivate in the field of intelligent manufacturing, constantly innovate and make breakthroughs, and provide global customers with more high-quality and efficient products and services. We firmly believe that with the joint efforts of all staff, Airstorm will be able to make more brilliant achievements in the field of wire harness processing!