FAKRA Automatic Production Line

Application

TD-FAKRA Automatic Producion Line can meet the processing of TE MATE AX(Fakra Mini) of products.It covers automatic processing from stripping,crimping sleeve,cutting and turning shielding,stripping insulation,crimping center contact,crimping outer contact,concentricity and insertion depth detection,etc,.Six crimping system can meet the single-end,double-end same and different terminals processing at the same time.Other series of products can be customized with this platform.

Advantages

Can be single side, double side processing, to meet clients flexible requirement

≤9S/per cable(A&B side), efficient processing

Modularization: Each station is independently desioned for easy maintenance and fast delivery

Magnetic suspension assembly line is adopted to high-precision positioning machining

Original opening downward sleeve direct crimping technology, meet the material various packing

Can be customized to meet the mainstream Fakra manufacturers of all generations of products

Client MES easy to connect

Design concept of flexible extensible function (Option Auto pre-feeding and cutting, Insulation voltage test, Plug housing function module)

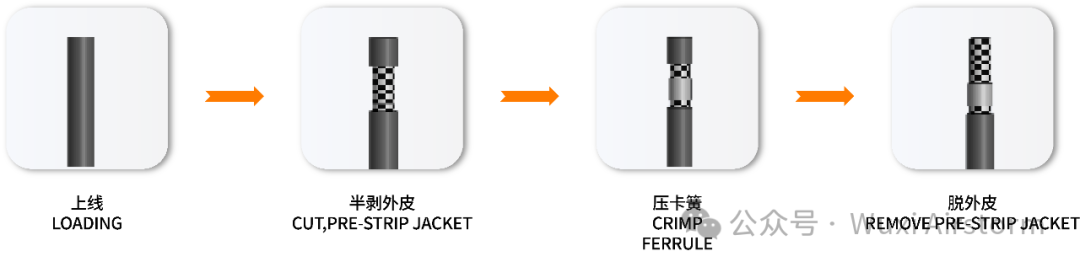

Processing

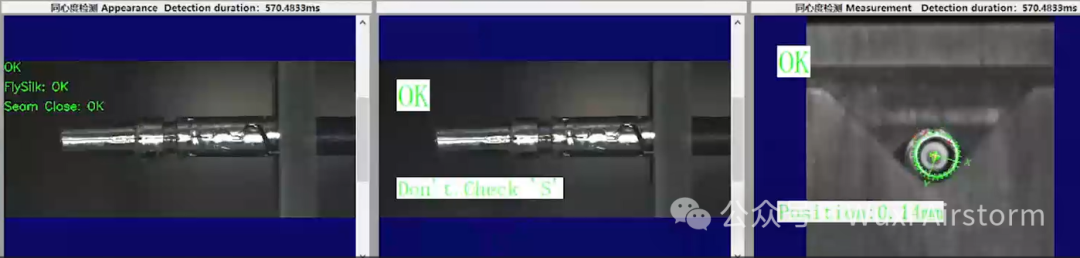

Partial Detection Means

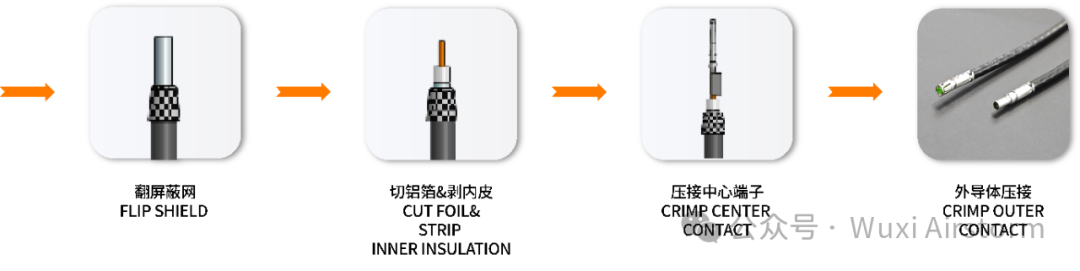

REMOVE PRE-STRIP JACKET & FERRULE CCD:

360 ° field of view coverage

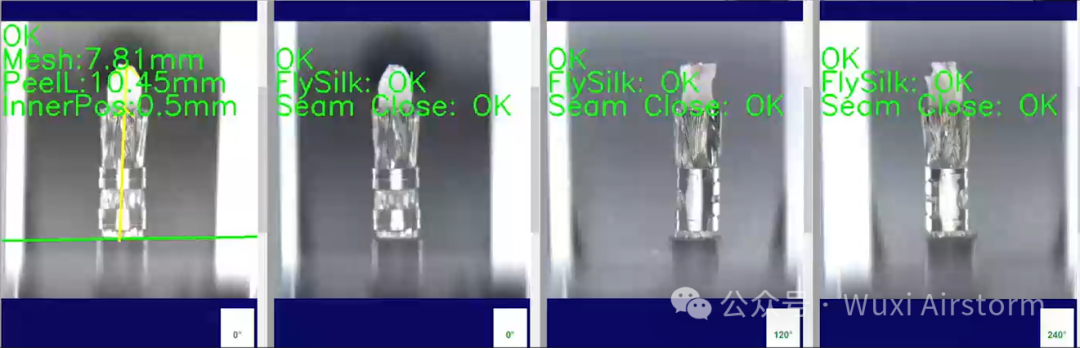

CENTER CONTACT VISION CHECKING:

360° check the crimping status

CONCENTRICITY VISION CHECKING:

Technical Spec

Processing Length:≥90mm(single-end);≥380mm(U-shaped)

CT:≤9S/per cable(A&B side)

Changeover:≤15min(Empty materials+change applicator+ feeding,Excluding inspection time)

OP:1 headcount/line

Compatibility:Option additional station

Power Voltage:380V AC(Three-phase five little system)

Air source:5-7Bar

Overall Dimension(L*W*H):9Mx1.85Mx2M (Excluding tri-colour light)